Graeme Vagg

Click on the photos to view full size version!!

1. I found a few photos of my Long Beach steam trike project and the

VW steam car based on the fastback body. The trike was a 2 seater

and could do 25 mph with a 50cc bump valve uniflow engine and gas fired

Smith boiler.

2. The VW conversion used a 4 cylinder Project Steam 77 and Doble type

boiler with a spinning cup burner. I still have the power plant components

but did not keep the car body as I wanted something better. It was

a cheap platform that allowed a whole system to be tested at the time.

3. Barrett Mercury 6 steam conversion - 1976. Mounted on

a VW bug floor pan with engine connected to the VW transaxle by chain drive.

The monotube generator is a Doble type on its side with a pressure atomising

burner. The same type of boiler has been used by both Vagg and Barrett

is this configuration or vertical with downward firing with 3 different

burners, namely pressure atomising, air atomising or spinning cup.

My options for solid fuel firing are horizontal or vertcal upwards firing.

Design considerations for any location include: space available, weight distribution, support arrangements for the tube nest, flue arrangement, air blower requirements to get combustion products through the layout and eventually to atmosphere, mishap management (such as where does fuel drip if there is a misfire or flame out?), ash collection arrangements for solid fuel burners. From an operational point of view you can put a monotube boiler in any position you like and have space for. There would be no restriction on a pressure atomising burner. The spinning cup burners work equally well in horizontal or downward firing positions but would need a slight modification to the cup and fuel supply arrangement for vertically upwards firing. So a lot of design freedom all round.

4. Vagg Barrett 2 cylinder VW steam conversion. 1976. This engine

replaced the Mercury 6 engine and reduced steam consumption by 50%.

5. Vagg Barrett pressure atomising burner. This was the original

oil burner used for the 2 cylinder VW conversion road tests and had a fixed

output of 1 US gal/hr that could maintain the test chassis at 30 mph around

the back streets of Pomona Ca.

4. Barrett Triumph Spitfire Steamer. This was the second generation

Barrett steam car and used an RJ Smith steam system and a 4 cylinder mercury

outboard based engine with various valve gears developed by Barrett.

Car was displayed at Los Angeles Car Show around 1975.

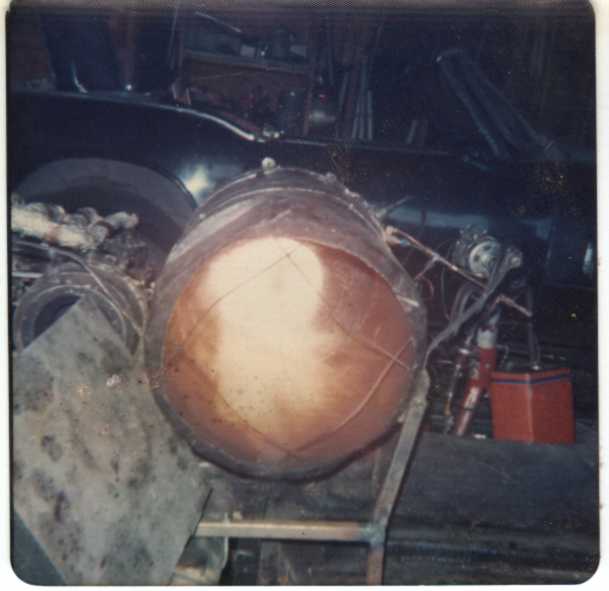

5. Doble Boiler showing water wall tubes around combustion chamber.

6. Here is another one I forgot and you should have more of this anyway.

It is the under hood view of the Besler GM steam car power plant.

7. I found two pages of colour copies of pictures sent to Project Steam

77 members back in 1976 that include some already posted but give a more

complete picture.

The burner series shows an experimental burner that used two 5 gallon paint tins for an air casing and tested outputs from 1 to 6 us gal/hr. Test was done in Pete Barrett's back yard and gave the basis for a new burner for Barrett's VW steam project.

My car was built on an extended VW floor pan to take a Fraser Nash replica fibre glass body kit (available in USA at the time). The boiler had the new spinning cup burner developed as part of PS77. I was unable to get a sponsor to leave the car in USA in 1977 when I had to return to Australia so the chassis and wheels were sold and the steam plant and instrument panel returned to Australia where it was used in the VW fastback trials and is now set aside for a similar roadster project when I have time to devote to it. The purpose of the exercise was to show that it was possible to put together a modern steam car that looked good and was affordable, namely less than the cost of a new family sedan at the time.

8. While on a roll I will keep going. Here is what I found this afternoon.

8.1 My greatest moment in steam was meeting Barney Becker at

his home in San Fransicso in 1976 and having a drive in his beautiful Doble

E14.

8.2. Roy Renner arranged the visit and is shown here beside the

car. Roy encouraged me to do something special in steam development and

this led to Project Steam 77 being born.

8.3. Under the hood of Doble E14.

8.4. The engine compartment of the Besler GM steam car.

9. Here are two pictures relating to my first steam car project that ran from 1962 to 1968.

9.1 Original Vagg V4 Uniflow Expansion single acting engine with inlet

poppet valves. Bore and stroke were 2.25" and 2". Engine was

designed for direct drive to a fixed differential and had a variable cut-off

cam shaft with 4 forward positions, neutral and reverse. The engine

was designed and built during spare time while undertaking my naval engineering

training at the Royal Naval Engineering College, Manadon, at Plymouth,

Devon, UK. Various parts had to wait until I learnt how to make them

- such as pattern making, iron and aluminium castings, machining and heat

treatment etc. One challenge for the instructors was the method of

making a heat treated variable cut off cam shaft. The instructor

said the item I described couldn't be made. My response was that

ity must be possible as the Williams engine had a camshaft that fitted

the performance requirement. I did not know until some 40 years later

that the Williams camshaft was fabricated with separate cams fitted so

was not made in one piece like mine. So with blind faith we made

a one piece unit.

My training finished late 1965 and the engine and boiler parts were shipped back to Australia for completion in 1966 when they were fitted to a new chassis (a Triumph Herald for local insurance compliance requirements) for testing. As the testing program commenced, two developments in the USA made the engine obsolete. First the infinite variable rotary valve design by Richard Smith gave very precise control of engine power at any speed and was virtually silent, Second the use of soluble oil in steam allowed sump lub oil to be eliminated from the system. The engine had automobile shell bearings so was not suitable for soluble oil lubrication so I quickly designed and built a slightly larger engine with a roller crankshaft and rotary inlet valve within about 2 months in about 80 hours of actual working time.

9.2 The car body selected for the Vagg Steam Car in 1962 was

the UK built Falcon Caribbean fibreglass kit made for pre-war Ford 8 and

10 chassis. It was light, attractive and had a suitable shape to accomodate

the steam plant in normal space allocated for a petrol engine and drive

train. An operational kit car was purchased in 1962 and a second

chassis with independent front and rear suspension was purchased for.

This had to be rebuilt to fit inside the body shell. The car was

registered for road use in UK and Australia and was driven with various

petrol engines while waiting for the steam plant. Steam car development

work ceased in 1968 when the body shell roof was wrecked in a wind storm

at a painter's workshop. The loose body was on a trailer and the

wind blew it off and it landed upside down. A commercial developer

for the steam plant had been found but expected applications were only

for boats and industrial equipment. A second developer, wanting a

steam engine for a new sports car project, offered me one of his cars as

a substitute for mine. Commercial developments then commenced. Steam

club activity did not start again until late 1974 when I had a Navy posting

to Long Beach Naval Shipyard for 2 1/2 years. Long term steam contacts

Richard J Smith and Peter Barrett were only 20 minutes or one hour away

and the rest is history.

Karl, we did know about you but you had moved elsewhere so we did not meet. Just think what we might have done if you had been involved as well.

9. Here is a clear picture of one of my V4 rotary inlet valve, uniflow

exhaust engines. It is similar to the one in USA now owned by SACA

President, Tom Kimmel. These engines have a 3" bore and 2" stroke

and a roller bearing crankshaft lubricated by soluble oil in the steam.

The RJ Smith type rotary valve was developed separately by Graeme Vagg

from a sample single cylinder valve made by Bill Jones, Sydney, Australia

following consultion with Richard J Smith. The valve had infinite

variable cut off from zero to 80%, both forward and reverse. A spectacular

feature of the engine was running it at 4,500 rpm on no load and throwing

it into reverse in about one second and repeating the exercise several

times in quick succession.

10. The prototype engine above was used to road test the first Vagg steam car chassis at the RAN apprentices school at HMAS Nirimba, Quakers Hill, NSW, Australia in 1968. This event is still a great bar room topic at Navy engineering reunions. A sponsorship to develop the design for commercial (non vehicle) applications followed. Before this orders for several engines had been received and agreed for production by the sponsor. By 1976, direct drive engines were out of favour and simpler fixed valve engines running at higher steam conditions with a transmission, were giving better results on the road. There have not been enough new steam engines in cars to settle the debate on this topic but the comparisons found in the Barrett car that used both types of engine in the same chassis were light years apart.

11. Doble E14 Exhaust Turbine Condenser Fan. The fan shroud

can be seen between the boiler and condenser.

12. Williams Steam Roadster 1961. This attractive picture

was well circulated in 1961 by Light Steam Power in a brochure and on the

magazine cover and was the inspiration for me to build a modern steam car.

My interest commenced some 6 years earlier when I read an article in a

motoring magazine about a car that pulled up to a service station without

noise, picked up some waste sump oil for free fuel, topped up the water

tank and drove quickly off. Way to go I thought. Sounds like

the reporter spotted a Stanley Steamer. Anyway the Williams steam

engine was far too expensive for me at the time so I bought a stack of

plans from Light Steam Power and started to build my own system during

my engineering course. By 1966 I had a system a bit like the Williams

one for 1/10 the cost.

13. Barrett Mercury Steam Conversion. This engine was used

in the Spitfire project and used twin rotary inlet valves and uniflow exhaust.

14. Mercury Steam Conversion fitted in the trunk of the Barrett

Steam Triumph Spitfire. This car had an independent rear suspension

with a fixed differential so mating a steam engine to it was quite easy.

Valve and steam system development was an on going process involving extensive

correspondence with Graeme Vagg in Sydney, Australia commencing in about

1966 when both started building Smith steam systems and needed to develop

designs further.

15. Barrett Steam Triumph Spitfire with front mounted R J Smith

type monotube steam generator made by Peter Barrett. This car was

used on the road until 1975 when it was replaced with a VW based vehicle

that led to the current steam sports car being built.

16. Barrett Steam Bicycle with Smith type flash steam plant.

Single cylinder engine had a bump inlet valve and uniflow exhaust.

I think rider is David Barrett.

17. Close up view of Barrett Steam Bicycle power plant.

These were quite popular in the early 1970s and a number were built.

I used a similar plant in the steam trike project.

18. Barrett Steam VW Power Plant. The main components,

namely the 2 cylinder engine, monotube boiler with spinning cup burner,

lube oil centrifuge, and throttle valve are clearly shown. The engine

uses poppet inlet and exhaust valves and was developed from the original

Project Steam 77 design that also only used 2 cylinders in this car.

The whole power plant has been progressively upgraded over time to improve

component reliability.

This page powered by ![]() Last updated on Sept 29, 2002. Copyright © 2000-02 Karl A. Petersen karlpete@yahoo.com .

Last updated on Sept 29, 2002. Copyright © 2000-02 Karl A. Petersen karlpete@yahoo.com .